Introduction

Your garage floor takes more abuse than almost any other surface in your home. Hot tires, road salt, oil drips, brake fluid, lawn equipment, dropped tools, rolling tool chests, and jacks all test the limits of bare concrete. Because the garage is often the largest uninterrupted slab of concrete in the house, the floor also becomes the visual foundation of the entire space.

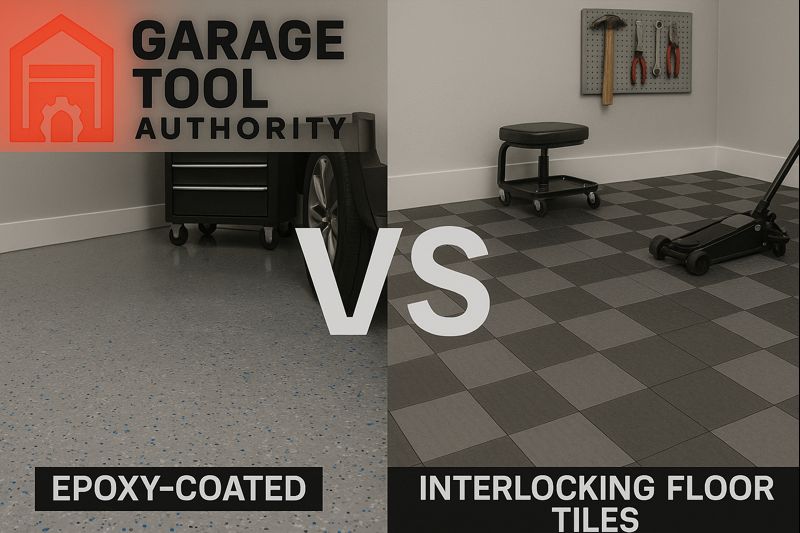

A quality garage floor system improves durability, cleanliness, lighting, and resale appeal. The challenge is choosing the right system for how you actually use your garage. Some options excel at chemical resistance but require extensive prep. Others install quickly but behave differently under heavy tools or wet conditions.

This guide compares the two most common garage floor coating options and the two most common garage floor tile options, then provides practical recommendations based on real-world usage scenarios.

Overview of Garage Floor Coatings vs Tiles

Garage Floor Coatings

Garage floor coatings are liquid-applied systems that chemically or mechanically bond to concrete. Once cured, they create a sealed, continuous surface that resists staining, dusting, and chemical damage.

- Seals porous concrete

- Improves chemical and abrasion resistance

- Creates a seamless, finished appearance

The tradeoff is preparation. Coatings are only as good as the bond to the concrete beneath them. Moisture, oil contamination, or inadequate surface profiling can lead to peeling or bubbling.

Garage Floor Tiles

Garage floor tiles are modular, floating systems—most commonly made from polypropylene—that interlock over the concrete slab. They do not bond to the floor and can often be installed without heavy prep.

- Fast installation

- Minimal surface prep

- Replaceable individual tiles

- Portable and renter-friendly

Tiles hide imperfections rather than fixing them. Dirt and moisture can collect beneath the surface, requiring occasional lift-and-clean maintenance.

In-Depth Comparison: Garage Floor Coatings

| Product / Type | Cost (Approx.) | Durability | Installation Difficulty | Appearance | Maintenance | Notable Features |

|---|---|---|---|---|---|---|

| Rust-Oleum EPOXYSHIELD (Epoxy) | $120–$220 | Good with proper prep | Medium–High | High-gloss showroom finish | Easy mop/clean | Long working time, widely available |

| Rust-Oleum RockSolid Polycuramine | $250–$350 | Very high | High (fast cure) | Modern high-gloss | Easy wipe-down | Fast cure, high chemical resistance |

Rust-Oleum EPOXYSHIELD Garage Floor Coating

Rust-Oleum EPOXYSHIELD is one of the most common DIY epoxy systems available. It offers excellent aesthetics and good chemical resistance when applied to properly prepared concrete.

Check current EPOXYSHIELD pricing on Amazon

Pros:

- Long working time for DIYers

- Glossy, professional appearance

- Lower cost than premium systems

Cons:

- Longer downtime before vehicle use

- Highly sensitive to surface prep

- Can discolor with UV exposure

Rust-Oleum RockSolid Polycuramine Coating

RockSolid Polycuramine is positioned as a premium, fast-curing alternative to traditional epoxy. It is designed for higher durability and significantly reduced downtime.

Check current RockSolid Polycuramine pricing on Amazon

Pros:

- Drive-on-ready in about 24 hours

- High abrasion and chemical resistance

- Modern, clean finish

Cons:

- Short working time increases install pressure

- Higher upfront cost

- Repairs can be more noticeable

In-Depth Comparison: Garage Floor Tiles

| Product / Type | Cost (Approx.) | Durability | Installation Difficulty | Appearance | Maintenance | Notable Features |

|---|---|---|---|---|---|---|

| RaceDeck Interlocking Tiles | $3.50–$7.00 / sq ft | High | Low–Medium | Clean, professional | Sweep/vacuum | Strong tile structure, modular |

| Swisstrax Interlocking Tiles | $3.00–$6.50 / sq ft | High | Low | Race-garage aesthetic | Surface clean + lift/clean | Vented drainage design |

RaceDeck Garage Floor Tiles

RaceDeck tiles are known for their solid feel, long brand history, and clean modular appearance. They are commonly used in workshops, show garages, and professional environments.

Check RaceDeck-style garage tile pricing on Amazon

Pros:

- Strong under rolling tool chests

- Replaceable individual tiles

- Professional appearance

Cons:

- Small hardware can fall into seams

- Hard surface for long standing sessions

Swisstrax Garage Floor Tiles

Swisstrax tiles emphasize airflow and drainage through vented tile designs, making them popular in wet or snowy climates.

Check Swisstrax-style garage tile pricing on Amazon

Pros:

- Excellent water drainage

- Fast DIY installation

- Highly customizable layouts

Cons:

- Dropped hardware can be hard to retrieve

- Periodic under-tile cleaning required

Recommendations by Garage Use Case

Daily Driver & Storage Garage

Epoxy coatings provide the best balance of cost, appearance, and easy maintenance when proper prep is performed.

Fast Turnaround Garage

Fast-cure polycuramine or polyaspartic-style coatings are ideal when garage downtime must be minimized.

Snow Belt & Salt Exposure

Vented tile systems or sealed coatings both perform well, depending on tolerance for under-floor cleaning.

Workshop or Mechanic Garage

Seamless coatings offer better performance for dropped hardware, welding, grinding, and heavy tools.

Show Garage or Enthusiast Space

Interlocking tiles deliver maximum visual impact and easy design customization.

Conclusion

Garage flooring is a functional upgrade that also dramatically improves the look and usability of the space. The best system depends on how you use your garage, how much prep work you’re willing to do, and how quickly you need the space back.

Coatings deliver a seamless, professional surface when properly installed. Tiles offer flexibility, speed, and visual customization. Choose the system that aligns with your real-world needs, not just marketing photos.

References & Further Reading

- Rust-Oleum EPOXYSHIELD Product Information

- Rust-Oleum RockSolid Polycuramine Information

- RaceDeck Official Site

- Swisstrax Official Site

- Concrete Network – Garage Flooring Comparisons